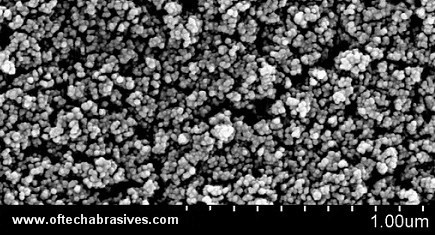

OFTech Nano-diamond is made from the detonation of high power explosives under minus balance of oxygen. The detonation brings out a proper diamond-growing condition with high temperature, super high pressure and isolated carbon atoms. Nanodiamond is different from normal synthetic diamond. It is round without any edges and corners and its crystal size is about 3-15nm.

Technical Parameter:

|

Item

|

State

|

Others

|

|

Appearance

|

Grey powder or slurry

|

|

|

Shape

|

Rounded shape

|

TEM

|

|

Crystalline

|

Mono-crystal

|

X-ray diffraction

|

|

Crystal size

|

3-15nm

|

SAXS

|

|

Particle size

|

40,60,80,100,150,200nm

|

Nanotrac UPA-150

|

|

Density

|

3.00-3.50g/cm3

|

|

|

Spec. surface area

|

300-420m2/g

|

BET Adsoption

|

|

Chemical composition

|

C:>90%、O:4-6%、N:1-2%、H:<1%

|

Element analysis

|

Features:

- High dispersibility and high dispersion stability

- Various particle sizes to meet different request

- High purity, impurity metal is below 10ppm

- Excellent polishing performance, surface roughness is below 1nm

- Excellent wear resistance, corrosion resistance and thermal conductivity

Applications:

- As high precision abrasives, used for the surface finish of magnetic heads, rigid discs

- Additives to lubricant and engine oil to improve the running performance of industrial machines and vehicles, reduce down time, prolong service life

- As hardening and wear resistance agent, used for the electroplating films on molds, tools, metal components to improve their wear resistance, surface hardness, and service life

- Reinforced additives to metals, rubbers and plastics

- Encapsulation materials used for IT production

- Used in magnetic record system

- Field Emission, CVD film